Since 1975, precision is our strength

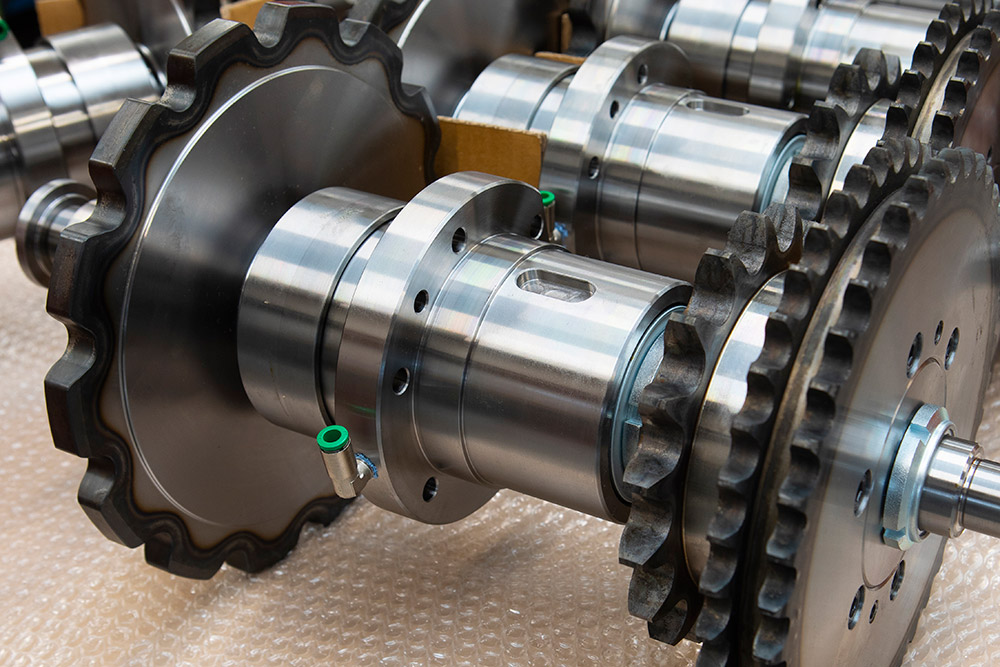

For over 50 years, 3M Mazzucchetti has specialized and been known for precision machining such as: turning, milling and wire EDM, of small and medium/large sized components; over time it has also been able to implement and develop an efficient department dedicated to the assembly and testing of mechanical groups, all always according to technical specifications.

THE COMPANY

From the technical specification to the finished product: the processes

At 3M Mazzucchetti, each phase of mechanical processing is carried out with care and precision, from CAD/CAM programming to turning, milling and EDM.

The production process is managed internally and tracked with the MES (Manufacturing Execution System), to guarantee quality, efficiency and fast delivery times.

Our machinery

Technological and cutting-edge machinery combined with high expertise: translates into a guarantee of precision.

Over 90% of our machines are interconnected

Tracked and

certified quality controls

3M Mazzucchetti has a wide range of instruments dedicated to dimensional control, used during the production cycle.

From traditional instruments, to coordinate control machines, to millesimal optical microscopes, periodically calibrated and certified, they allow us, upon customer request, to trace and certify production.

A warehouse

covered

of 600 m2

We have a large warehouse, mainly dedicated to the storage of finished products.

Management is automatic and optimized thanks to our MES/ERP management system.

This allows us to have real-time control of stocks, complete traceability of items and more efficient internal logistics, to satisfy our customers.