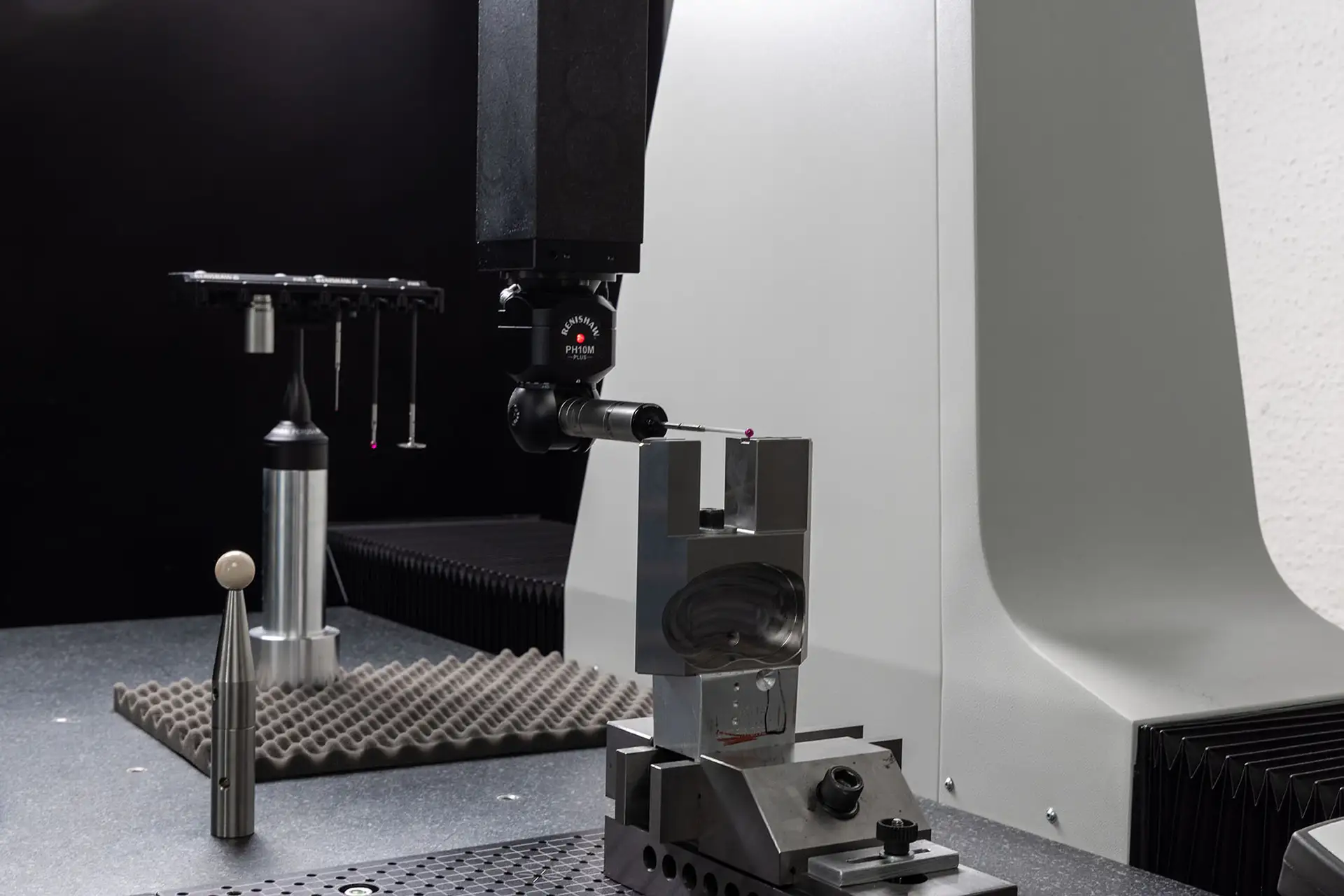

Millesimal checks tracked and certified with WENZEL 3D coordinate measuring machines and KEYENCE optical vision system

Automatic machines for dimensional quality control

For medium-large items, we have Nr. 2 latest-generation WENZEL 3D coordinate automatic measuring machines, in an isolated and air-conditioned environment to ensure precision and repeatability of measurements. The maximum measurement dimensions are x800 y1000 z600, with continuous scanning and millesimal resolution.

Connected to our MES, to also ensure traceability and digitalization of measurements.

Optical measurement system

For small items, we also have a KEYENCE microscope, equipped with two optical vision systems and optical probe, with millesimal resolutions.

Lathes

The turning department consists of 10 MORI SEIKI lathes, NL and NLX series with bar pusher or automatic gantry loader, allowing production even in unattended shifts, but anyhow monitored via MES. The machines are complete with counter spindle and tool presetting to ensure speed and precision.

Lathe CNC DMG Mori Seiki NLX2500SY/700

motorized c-axis and y-axis counter spindle, turning diameter 350 mm, bar passage 80 mm, gantry loader

Lathe CNC DMG Mori Seiki NL2500SY/700

motorized tailstock, turning diameter 350 mm, bar passage 80 mm, gantry loader

Lathe CNC DMG Mori Seiki NL2500SY/700

motorized tailstock, turning diameter 350 mm, bar passage 80 mm, bar loader

Lathe CNC DMG Mori Seiki NLX2500SY/700

motorized c-axis and y-axis counter spindle, turning diameter 350 mm, bar passage 80 mm

Lathe CNC DMG Mori Seiki NLX2000SY/500

motorized c-axis and y-axis counter spindle, turning diameter 300 mm, bar passage 65 mm

Lathe CNC DMG Mori Seiki NLX2500SY/700

motorized c-axis and y-axis counter spindle, turning diameter 350 mm, bar passage 65 mm, bar loader l=3000 mm

Lathe CNC DMG Mori Seiki NLX2000SY/500

motorized c-axis and y-axis counter spindle, turning diameter 300 mm, bar passage 65 mm, bar loader l=2000 mm

Lathe CNC DMG Mori Seiki NL1500Y/500

motorized c-axis and y-axis tailstock, turning diameter 260 mm

Lathe CNC DMG Mori Seiki NLX2000SY/700

motorized c-axis and y-axis counter spindle, turning diameter 300 mm

Lathe CNC DMG Mori Seiki NLX2000/500

motorized c-axis and y-axis counter spindle, turning diameter 300 mm

Milling Machining center

The milling machining centre department has Nr. 10 DMG Mori Seiki CNCs available, including: 4 vertical double pallet machines and 6 horizontal 1,2, 6 and 11 pallet machines.

All work centers use tool holders with MAS BT40 attachment and have all the possibilities to perform measurements of the machined pieces directly in the machine thanks to RENISHAW measurement probes. The impressive tool magazines of these machines, guarantee a working continuity that widely covers unattended shifts.

Horizontal Centre DMG Mori Seiki NH5000DCG/40 stroke x730 y730 z850, equipped with 2 Pallets

Horizontal Centre DMG Mori Seiki SH5000/40 stroke x800 y700 z700, equipped with 6 Pallets

Horizontal Centre DMG Mori Seiki NH5000DCG/40 stroke x730 y730 z850, equipped with 2 Pallets

Horizontal Centre DMG Mori Seiki NH5000DCG/40 stroke x730 y730 z850, equipped with 11 Pallets

Horizontal Centre DMG Mori Seiki NH 5000 stroke x630 y600 z670, equipped with 2 Pallets

Horizontal Centre DMG Mori Seiki SH400 stroke x460 y510 z410 – equipped with 2 Pallets

Vertical Centre DMG Mori Seiki SV503/40 stroke x900 y450 z450, equipped with 2 Pallets

Vertical Centre DMG Mori Seiki MV-40E stroke x550 y400 z500, equipped with 1 Pallet

Vertical Centre DMG Mori Seiki SV503/40 stroke x900 y450 z450, equipped with 2 Pallets

Vertical Centre DMG Mori Seiki SV500B/40 stroke x1000 y450 z400, equipped with 2 Pallets

Tools presetter

ELBO NIKKEN Mod. E68LA

Tools presetter

ELBO NIKKEN Mod. E46LA

Tools presetter

ELBO NIKKEN Mod. E46B

Presetter

machines

Tools always ready for production and with the correct dimensions, sent directly in the machine and in our CAD/CAM. We have Nr. 3 Presetter ELBO NIKKEN series that are the latest generation machines for the presetting of the tools.

Thanks to the wide measuring range, it is possible to preset even large tools, for any type of processing.

Wire EDM (Electro Discharge Machining)

Spark electroerosion, also called EDM (Electric Discharge Machining), is a relatively new technology, which exploits the combined power of heat and electricity which through electrical contacts allow the fine erosion of metallic material.

It is a highly specialized manufacturing process, which we use for items ranging from 4 to 300 mm in size, with complex geometries and very tight tolerances, this technology also allows the choice of the level of surface finishing that you want to obtain.

Wire EDM machine SODICK serie SL600G

corsa X600 Y400 Z250

Wire EDM machine MITSUBISHI serie MV2400-S new generation M800

corsa X600 Y400 Z250

Wire EDM machine MITSUBISHI serie MV2400-S new generation M800

corsa X600 Y400 Z250

Assembly and testing:

precision, efficiency, quality

Our assembly and testing department is a strength point that allows us to offer a complete service to customers, from mechanical processing to delivery of the finished and tested group.

Thanks to highly qualified personnel, years of experience and a complete set of measuring instruments, test benches and structured control plans, we are able to efficiently and qualitatively manage the assembly of mechanical groups, both simple and complex.

Each phase of the process is tracked and controlled to guarantee maximum reliability, according to customer specifications and the highest standards in the sector.

👉 The result? Ready-to-use solutions, with reduced management times and guaranteed performance.

Contact us to find out how we can support your projects with a customized assembly and testing service.

Other machinery

Latest generation of automatic vertical warehouses,

interconnected to the MES

Laser marking machine ROFIN COMBILINE

Automatic cutting lines IMEF X-TECH series

Coordinate measuring machine TESA 3D MICRO-HITE series 3D,

axis travel x450 y500 z300

Altimeters MITUTOYO LINEAR HEIGHT series

Millesimal Digital Micrometers MITUTOYO

Certified Reference Blocks and Rings