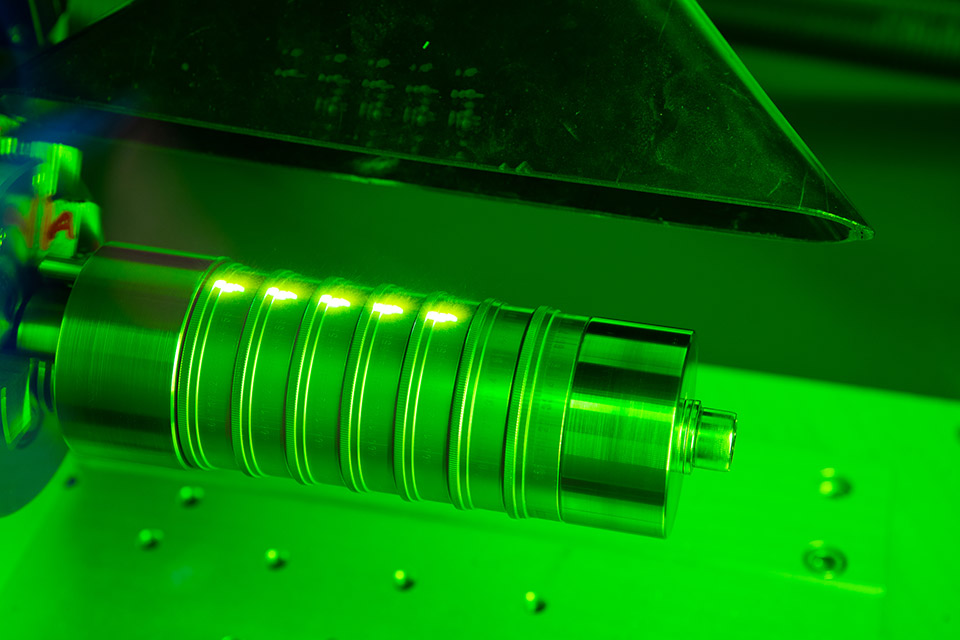

Turning

The turning department consists of Nr. 10 CNC lathes DMG MORI SEIKI, NL and NLX series, with bar pushers or pallets to load the pieces automatically, effectively allowing unattended production, but anyhow monitored by the MES.

The machines are complete with counter spindle, tool presetting and control instruments to guarantee speed and precision.

Milling

The milling department has Nr. 10 CNC machining centre DMG MORI SEIKI, NH, SH and SV series, including 4 Vertical and 6 Horizontal multi-pallet with 2, 6 and 11 pallets, effectively allowing unattended production, but anyhow monitored by the MES.

The presetting machines provide the correct presetting of the numerous tools present in the loaders, ensuring speed and precision.

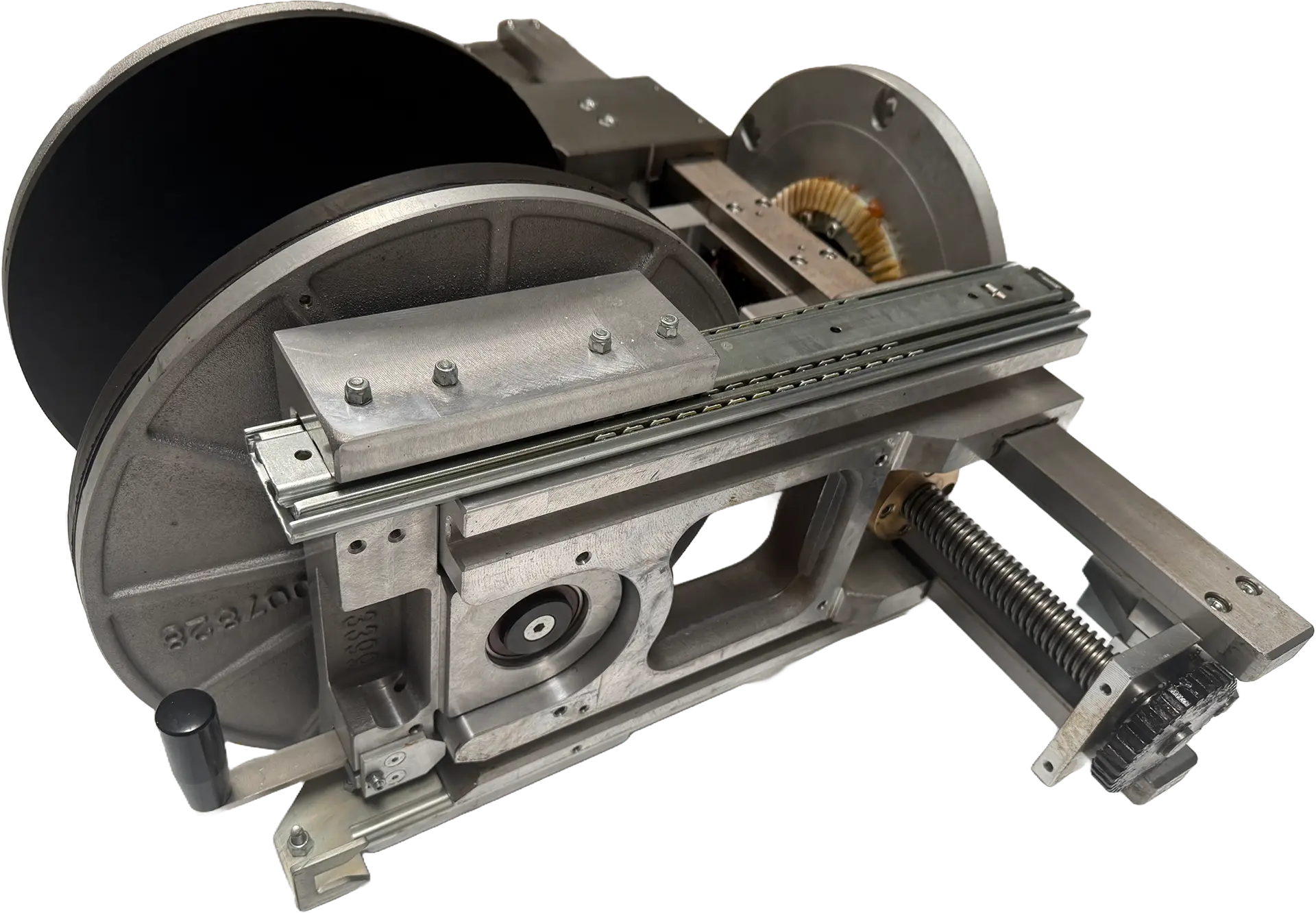

Wire EDM (Electrical Discharge Machining)

We have Nr. 03 CNC wire EDM machines for processing complex geometries: Nr. 2 MITSUBISHI MV2400S series and Nr. 1 SODICK SLC600G series.

Thanks to the erosive force of the electrical discharges, the metal is removed with millesimal precision and with the possibility of choosing the degree of surface finishing. These machines allow us to produce pieces with variable dimensions between 4 and 300 mm.

EDM machines also allow for unattended production, but anyhow monitored by the MES.

Cutting-edge machinery

Our machinery

Technological and cutting-edge machinery combined with high expertise: translates into a guarantee of precision.

Over 90% of our machines are interconnected

Tracked

and certified quality controls

3M Mazzucchetti has a wide range of instruments dedicated to dimensional control, used during the production cycle.

From traditional instruments, to coordinate control machines, to millesimal optical microscopes, periodically calibrated and certified, they allow us, upon customer request, to trace and certify production.

Contact us for a quotation

Write us to receive a free quote, our sales office is available to find the best value proposition for you.

Request information