ADVANCED DIGITALIZATION:

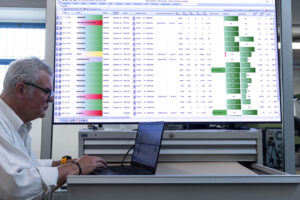

Monitoring and planning of each production phase thanks to the MES/ERP

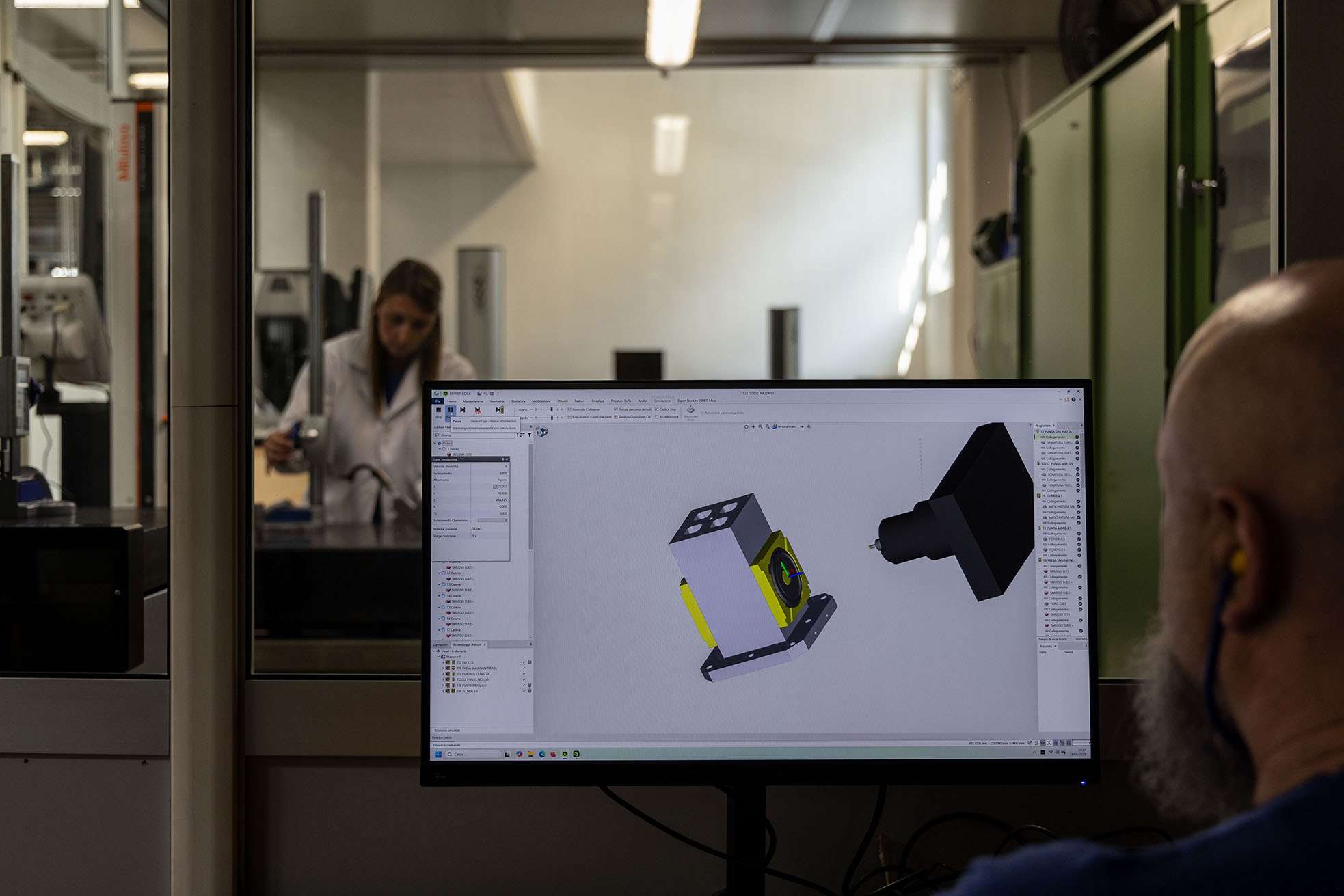

This year, 3M has chosen to take a major step toward efficiency and quality, relying on Mecmatica’s Manufacturing Execution System (MES) to manage and monitor the entire production cycle with precision, transparency, and high quality.

This software, designed “in production, for production planning and management,” integrates all the modules needed to track orders, from quotes to delivery notes.

With this investment, 3M not only automates and streamlines processes, but also aims to:

- Greater visibility into production times and actual costs;

- Achieve product traceability throughout the entire process;

- Traced and certified quality control upon request;

- Increased reliability and reduced human errors;

- Ability to respond quickly to changes, thanks to a system that allows for timely monitoring and intervention.

15 October 2025

News archive